New Supply Chains: 5 Powerful Tips to Master Market Entry

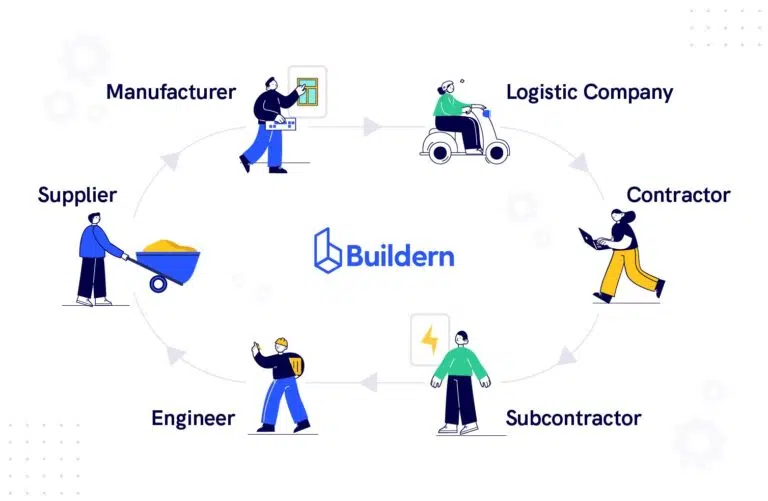

Entering new markets demands not only understanding local dynamics but also mastering the complex world of new supply chains. Effective management of new supply chains is essential for ensuring product availability, reducing costs, and responding to ever-changing demand. Whether you’re a startup or an established business expanding globally, these insights will equip you with the tools to succeed. Without solid new supply chains, market entry efforts can easily fall short due to delays, excess inventory, or poor customer satisfaction.

Understanding the Fundamentals of New Supply Chains for Market Success

Building new supply chains begins with critical foundational decisions such as selecting the appropriate sales channels, thoroughly understanding regulatory and customs requirements, choosing reliable logistics partners, and establishing efficient warehouse infrastructure. These operational pillars are essential to support a supply chain that can not only meet current demands but also scale and adapt as the market grows. Entering new and unfamiliar markets requires these choices to be carefully tailored to local regulations and consumer expectations, which can vary significantly across regions. Proper planning and preparation in this phase are crucial for laying the groundwork for long-term success.

However, having the right operational setup alone is not enough to guarantee success. The true challenge lies in the supply chain’s ability to quickly adapt to sudden shifts in demand and potential disruptions in the supply network. Being agile and responsive can make the difference between gaining a strong market share and losing it to more flexible competitors. Therefore, early investment in resilient and flexible systems is vital for companies to withstand challenges, maintain continuity, and ensure sustainable operations in dynamic and often unpredictable environments.

Powerful Role of Real-Time Data in New Supply Chains

Access to real-time data has become a true game-changer for modern supply chains, especially when entering new markets. Without timely visibility into sales trends, manufacturers often find out about sudden spikes or drops in demand only when urgent orders flood in. This reactive approach leads to costly delays, increased operational expenses, and missed revenue opportunities. A striking example of this was seen last year in Icelandic supermarkets, which experienced a cucumber shortage after a viral TikTok salad recipe caused an unexpected surge in consumer demand. This incident clearly demonstrates how quickly consumer trends can disrupt supply chains and why relying on outdated data is no longer viable.

To address this challenge, integrating real-time sales and inventory data into supply chain management systems is essential. Such integration allows companies to anticipate demand fluctuations and proactively adjust production schedules and logistics strategies. As a result, stock availability improves, waste and overproduction are minimized, and supply chain partners build stronger, more reliable relationships. Ultimately, this dynamic data-driven approach boosts overall supply chain resilience and leads to higher levels of customer satisfaction and loyalty in competitive new markets.

Strategic Inventory Management and Demand Visibility in New Supply Chains

Many businesses attempt to mitigate uncertainty by increasing inventory levels, but this strategy has significant drawbacks. Around 80% of small and medium-sized businesses struggle with excess inventory and poor forecasting, leading to wasted resources and increased storage costs. Maintaining high inventory ties up capital and space, often without effectively addressing demand volatility.

Moreover, recent trends show a drop in companies relying heavily on inventory as a risk management tool—from 59% to 34% in 2024—mainly due to rising storage expenses. This shift underscores a critical insight: inventory alone cannot replace accurate, timely visibility into demand for successful new supply chains. Instead, synchronized planning based on real data is far more efficient and cost-effective.

Adopting technologies that enable demand sensing and predictive analytics allows businesses to optimize inventory levels, balance stock across warehouses, and reduce holding costs while maintaining service quality.

Collaborative Planning Models That Strengthen New Supply Chains

Collaboration between suppliers and distributors is crucial for optimizing new supply chains. Two main planning models dominate:

- Order-based planning: Supply volumes are determined only by distributor purchase orders, limiting supplier access to real-time sales data and often resulting in reactive, less efficient supply chain management.

- Data-driven planning: Distributors share secondary sales data through CRM or other systems, enabling suppliers to monitor demand shifts and adjust production swiftly. This approach promotes proactive responsiveness and stronger alignment between partners.

Adopting data-driven planning fosters agility and resilience, allowing new supply chains to better absorb shocks and capitalize on emerging opportunities. Such collaboration also enhances trust and transparency, key factors in long-term partnership success.

Technological Innovations Driving the Future of New Supply Chains

Advanced technologies like AI, machine learning, and blockchain are revolutionizing new supply chains. AI-powered demand forecasting improves accuracy by analyzing multiple variables and historical trends, while blockchain enhances transparency and trust among supply chain partners by providing immutable transaction records.

Implementing these technologies helps businesses optimize inventory, reduce lead times, and ensure compliance with complex international trade regulations—key advantages when entering new markets. Additionally, IoT devices and sensors improve real-time tracking of goods, enabling better logistics coordination.

Companies embracing these innovations gain a competitive edge, able to respond faster and more effectively to market dynamics, thereby strengthening their new supply chains.

Case Study: Leveraging Technology in New Supply Chains

A leading global retailer recently integrated AI-based demand analytics and blockchain tracking across its new supply chains. This resulted in a 20% reduction in stockouts and improved supplier collaboration, boosting customer satisfaction and profitability. Such case studies demonstrate the tangible benefits of investing in supply chain technology, especially when navigating new markets where uncertainty is higher.

Overcoming Challenges in New Supply Chains

Despite their benefits, new supply chains face obstacles such as regulatory complexities, geopolitical risks, and fluctuating transportation costs. Proactive risk management and continuous market analysis are essential to navigate these challenges. Companies must stay informed about trade policies and regional political developments that can affect supply routes and costs.

Moreover, developing strong relationships with local partners and investing in staff training can significantly improve supply chain reliability and adaptability in unfamiliar markets. Understanding local culture, business practices, and consumer preferences helps tailor supply chain strategies for better acceptance and performance.

Essential Best Practices for Managing New Supply Chains Effectively

To ensure the success of new supply chains, businesses should:

- Invest in real-time data integration for accurate demand sensing and quicker response.

- Adopt collaborative planning with transparent data sharing to align partners.

- Leverage technology to enhance supply chain visibility, agility, and compliance.

- Develop tailored risk management strategies that address new market challenges.

- Foster strong local partnerships and invest in workforce development and training.

Following these best practices will help businesses build resilient new supply chains that support sustainable growth and competitive advantage, especially when entering complex new markets.

Enhance Your Knowledge on Supply Chains

For further insights into supply chain management and market expansion, explore this comprehensive resource on SupplyChainBrain, a leading platform delivering the latest trends and strategies in global supply chains. Staying updated with industry best practices and innovations is critical to mastering new supply chains and ensuring successful market entries.

Discover more about optimizing your supply chain by reading our detailed guide on Supply Chain Optimization.

Table of Contents

- Understanding the Fundamentals of New Supply Chains for Market Success

- Powerful Role of Real-Time Data in New Supply Chains

- Strategic Inventory Management and Demand Visibility in New Supply Chains

- Collaborative Planning Models That Strengthen New Supply Chains

- Technological Innovations Driving the Future of New Supply Chains

- Overcoming Challenges in New Supply Chains

- Essential Best Practices for Managing New Supply Chains Effectively

- Enhance Your Knowledge on Supply Chains

Source: By supplychainbrain